Simcon

Simcon et

Accuform seront présent au

Congrès RTS 2019 : Rotomolding, Thermoforming and Blow-molding congress.

Le

Dr. Karel Kouba, PDG d'Accuform sera notre

conférencier sur la simulation du thermoformage et du soufflage afin d'y présenter ses logiciels

T-Sim® pour le thermoformage et

B-Sim® pour l'injection soufflage et l'extrusion soufflage, le développement en cours de la version

3D y sera aussi présentée.

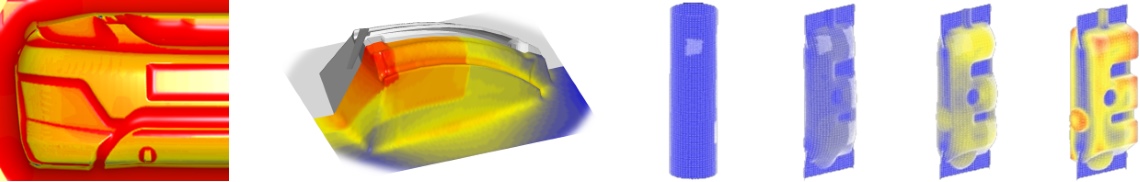

T-SIM® is based on a viscoelastic resolution model, it allows to simulate any type of thermoforming : positive forming, negative forming, assisted forming with plugs, … It’s user-friendly interface. Results obtained make it possible to optimize both the tooling and the thermoforming process, because 3D map and cut diagram allows the display throughout the simulation for : thickness, temperature, constraints, stretching.

T-SIM® can predict 2D/3D image distortion and pre-distortion (sticker, smart surface with printed touch sensors, and many other applications).

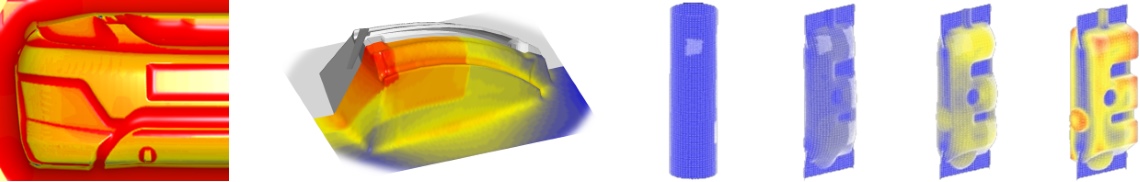

B-SIM® is a software that can simulate an injection blow molding or extrusion blow molding operation with ease. It offers an ergonomic interface by respecting a chronological order of the different phases to be carried out to arrive at a simulation.

Five steps are necessary :

- Creation of the preform/paraison or import of a preform/paraison previously made in CAD and then converted into an STL file

- Creation of the process in tabular form indicating the cycle time and pressure required

- Choice of materials : B-SIM® has a standard material database (possibility to enrich it with new material sheets)

- Thermal transfer coefficient and friction coefficient

Simcon et Accuform seront présent au Congrès RTS 2019 : Rotomolding, Thermoforming and Blow-molding congress.

Simcon et Accuform seront présent au Congrès RTS 2019 : Rotomolding, Thermoforming and Blow-molding congress.